Industrialization of Natural Dyeing and Printing of textiles

Dyeing is nothing but the process of colouring the fabric or cloth. More than 99% of textiles are dyed using chemicals. There are various problems associated with chemcial dyeing:

- A large number of the chemicals used for dyeing are harmful to humans and animals. 140,000 tonnes of sythetic dyes released into the enviromnet every year from chemical dyeing.

- Infact 20% of all water pollution in the world is caused by textiles dyeing waste.

- Textile dyeing uses large quanitities of water, of which 93% water from chemcial dyeing pricess cannot be reused.

- Did you know a T-shirt uses up 700 gallons of water and over 8000 chemicals to dye?

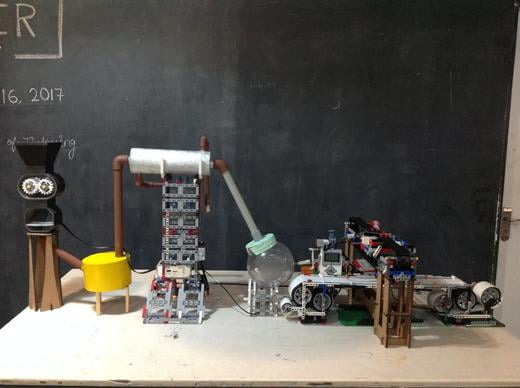

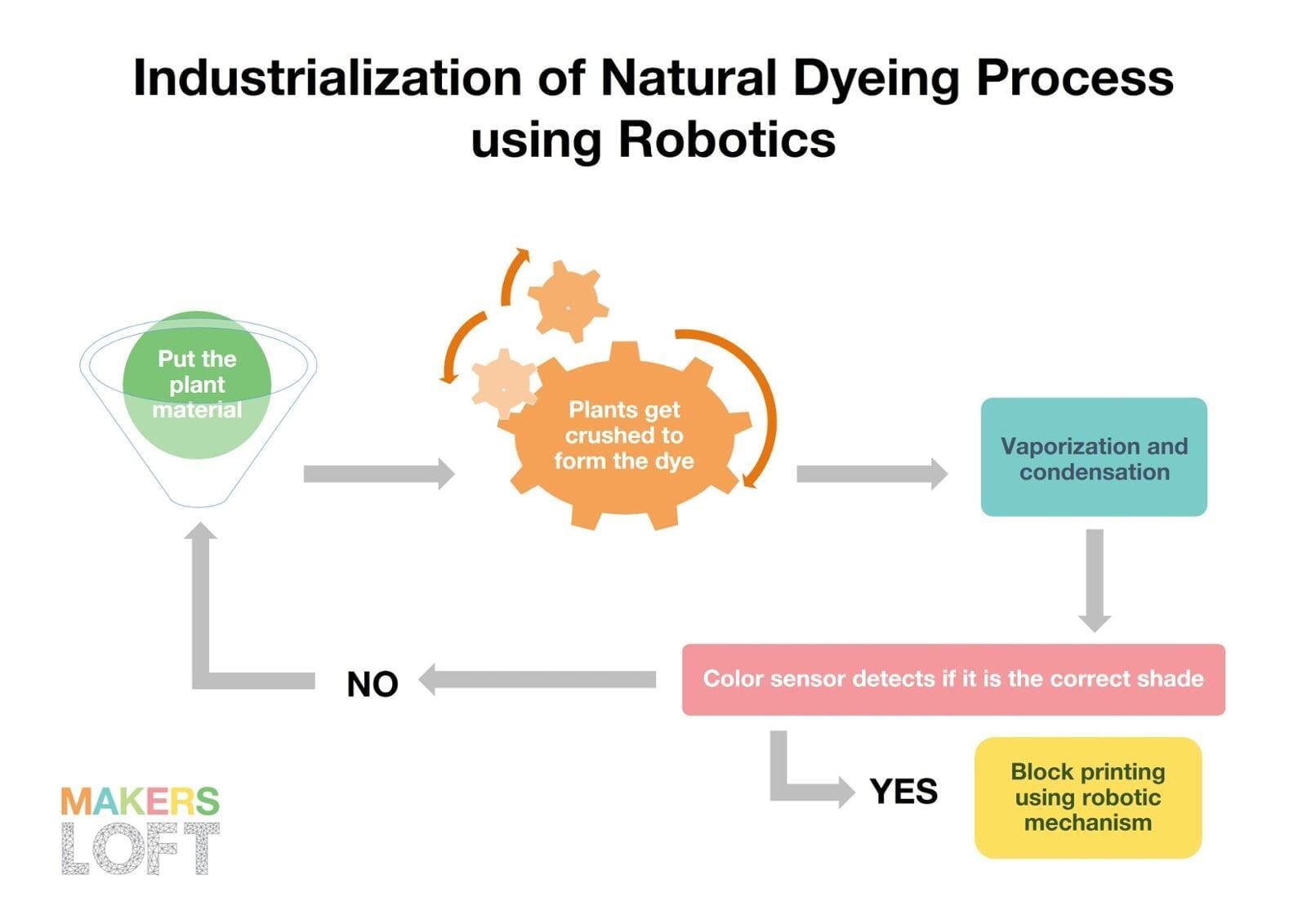

Our students thought of upgrading the natural dyeing process and trying to introduce it as the mainstream dyeing technique. We first crush the raw material and then vaporise and condense it to form the dye .We use a colour sensor to give us the feedback whether the dye is of the right shade or not. If it is of the wrong shade we can re-dye it to form the right. This upgraded version of natural dyeing is more efficient. We are solving the problem by reducing the need to re dye, increasing the chance to get the correct shade by detecting it using a colour sensor. By this process we can reduce usage of water as minimum as possible, we can save lot of times and this process takes us one step ahead in Sustainability.